Inspections

Conduct Safe & Efficient Inspections

Solar

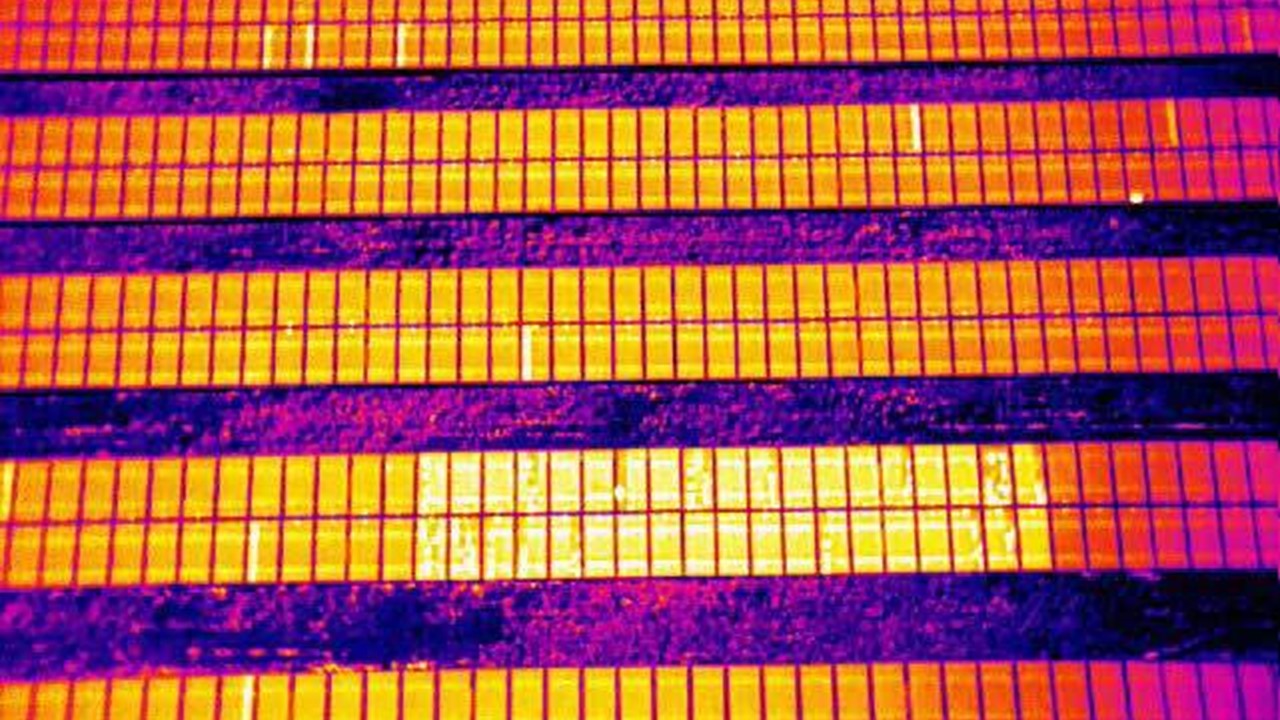

Drones equipped with thermal cameras offer many advantages for solar panel inspectors and operators of massive solar farms. In addition to being able to clearly view temperature anomalies on a crisp thermal image, thermal cameras can be used to scan installed solar panels during normal operation across large areas within a short time frame. Problem panels can be quickly identified, keeping energy production at optimum levels. Instead of sending inspectors out into the plant to check individual panels on foot, an overhead drone flight, recorded in 4K video, provides the image clarity needed to carry out initial inspections. Inspectors then are only required to investigate problem areas, significantly increasing their efficiency and productivity.

Wind

Wind turbines present unique challenges for maintenance inspections. Current methods involve hoisting staff to heights that present significant health and safety risks. As a result each inspection requires extensive downtime and meticulous planning before it can be carried out, reducing the overall efficiency of energy generation.

Conducting wind turbine inspections via UAVs is a significant improvement over existing methods. A UAV is able to fly precisely and accurately in close proximity to the turbine, taking away the need to put people at risk. Advanced onboard flight controllers and collision avoidance systems found on the leading-edge drones offered by Drone-Works ensure that a sudden gust of wind or pilot error will not result in a collision.

With high resolutions cameras up to 8K resolution, images are ideal for identifying fissures, cracks, or other indicators of structural stresses that may require repair. As all the data is stored on-board, it can be reviewed either at the point of inspection, or back at the office. These innovations allow inspection teams to increase their overall efficiency while reducing facility downtime.

Oil & Gas

Safety and efficiency are paramount to modern energy refining facilities and inspections are mission critical to maintaining operations.

Traditional inspection methods have always been challenging as facilities can cover large areas with complex structural layouts. UAVs allow for even the largest facilities to be inspected quickly from the air. State-of-the-Art drones provide simple, high altitude facility surveying as well as close proximity vertical inspection.

More demanding scenarios can draw on Drone-Works wide selection of products spanning the visible and thermal spectrums. However and whichever these advanced technologies are applied, these systems allow teams to quickly identify structural weaknesses, scan for hot spots, identify gas leaks and much more, empowering them to make decisions quickly and move more efficiently to remedial actions.

Power Lines

Power lines span vast distances and are the backbone of modern power grids. They present unique maintenance challenges due to their geographical dispersion, as well as their height.

Traditionally inspected by helicopter-based methods, they can be more easily and efficiently inspected using UAVs. Drone equipped inspection teams are able to begin aerial inspections mere moments after arriving on site, capturing high resolution photos and video, detailed enough for fine post-inspection analysis while the live feed will allow operators to see significant problems as they fly.

Nuclear

Nuclear power is one of the most efficient energy sources available today. However, nuclear facilities must be managed with stringent operational standards to ensure safety.

Nuclear materials also present serious safety risks to inspection staff, strengthening the case for remote solutions. Using UAVs for inspections in these situations allows the work to be carried out more quickly than traditional methods.

Drone mounted thermal cameras can detect potential leaks or structural stresses not visible to the naked eye. High resolution visible light cameras create a flexible platform that meets the varied needs of different inspection teams and scenarios.